for Industrial Nanoparticle Production

nanoparticle production processes

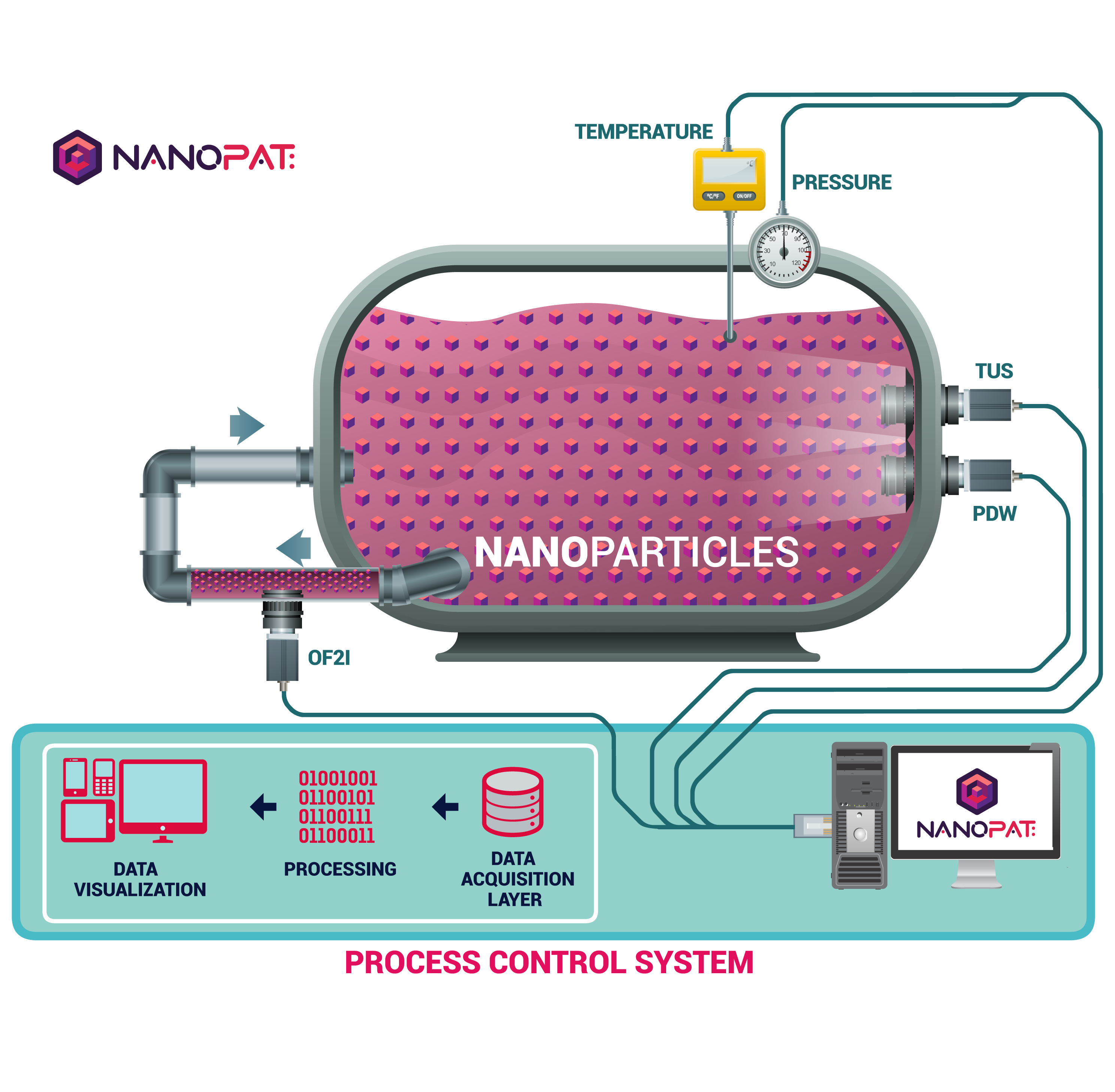

Photon Density Wave Spectroscopy

An inline process analytical technology capable of calibration-free quantification of light absorption and light scattering in highly turbid, highly concentrated liquid dispersions.

OptoFluidic Force Induction

An active, single particle based high throughput PAT based on induced photonic & microfluidic forces. It provides statistically relevant data streams for particles from 20 nm up to several microns.

TUrbidity

Spectrometry

A flexible optical technique for monitoring the evolution of suspending particles which size ranges from approx. 100 nm up to few microns.

About the project

While bulk materials have constant physical properties independent of their size, the physical and chemical properties of a nanoparticle are dictated by its size. Accurate characterisation of mean size, size distribution and shape is key to the efficient manufacturing of high-quality nanomaterials. The EU-funded NanoPAT project plans to use three new real-time analytical tools that overcome problems and limitations of conventional characterisation technologies. The new process analytical technologies (PAT) will be Photon Density Wave spectroscopy (PDW), Optofluidic Force Induction (OF2i) and Turbidity Spectrometry (TUS). The innovative technologies will be combined with new data analysis methods to provide, for the first time, real-time analysis of particles on the nanometre scale with sub-minute temporal resolution.

Our partners' expectations:

Prof. Dr. Ron Peters

Principal Scientist, Covestro AG“The new developed technologies of NanoPAT will provide to Covestro a useful tool for fast and accurate monitoring of particle properties of waterborne polyacrylates and polyurethanes, polycondensates and hydrids of it. Both in the R&D as in the production environment, the new technology will mainly contribute to production efficiency; approximately 5-10% of the reaction time can be saved (in terms of heating costs, manufacturing etc. and will easily sum up to millions euro savings per year)”.

Dr. Paulo Quadros

Business Development, FLUIDINOVA S.A."With NanoPAT technologies, we would improve our particle size analysis by going from off-line to on-line measurements reducing our time analysis in 10 days. We estimate that the acquisition of real-time data would improve the quality of our existing processes and products by 15 %. Moreover, with the use of NanoPAT tools, we expect an increase of productivity by 10 % and cost reduction of 20 %."

Dr. Thomas Pelster

Vice President R&D Precipitated Oxides, Evonik Resource Efficiency GmbH“For the first time we see the potential to overcome our sampling processes. Overall, Evonik has a global production capacity for all silica-based products of about 1 million metric tons/year with a current time-lag from sampling to data availability of 1 h., Thus, the reaction time on quality fluctuation is bigger than one hour, in which the process may run out of specification. The potential of reducing quality related costs can additionally also sum up to several 100,000€ per year.”

Dr. habil. Jean-Luc Dubois

Scientific Director, ARKEMA“The implementation of the online & inline particle measurements is foreseen to be made first in our existing plants using batch processes which is a low risk option. However, the implementation of a new continuous process which is higher risk – higher reward option which would generate higher energy savings (estimate of 40% or 13600 MWh/y), would lead to a significant CAPEX reduction of 45%, and will enable higher environmental impact reduction by a greater recycle of water and reduction of consumption of raw materials.”

Dr. Alexandros Zoikis-Karathanasis

CEO, CNANO"Surface modification of metallic components via electrodeposition is a well-established method. Cnano advances the electroplating method by the addition of NPs in the electrolytic baths to produce high quality nano composite coatings for a variety of components, covering a series of industry sectors. We act as an intermediate, between Research groups and the Industry, allowing the manufacturing business and market to adopt these technologies. Better control of the NP dispersion can enable tailored coating development."

Our objectives

Nano-scaled materials are abundant in different stages of industrial manufacturing. Physical and chemical properties of these materials are strongly dependent on their size. Characterisation of mean size, size distribution, and shape of nano-scaled particles is very critical for the quality and efficiency of manufacturing processes. Yet, conventional characterisation technologies still show manifold shortcomings which represent a major innovation obstacle for manufacturers of nanoparticles.

The NanoPAT consortium aims at closing this gap by the demonstration of 3 novel, real-time nano-characterisation Process Analytical Technologies (PAT), including real-time data handling for digital process monitoring and product quality control. Those will be validated in 5 different industrial ceramic, polymer and mineral nanoparticles manufacturing and converting environments. This implies that innovating PATs will be paired with new data-analytical technologies in order to provide, for the first time, a real-time analysis for manufacturing processes of particles in the nanometer scale with sub minute temporal resolution.